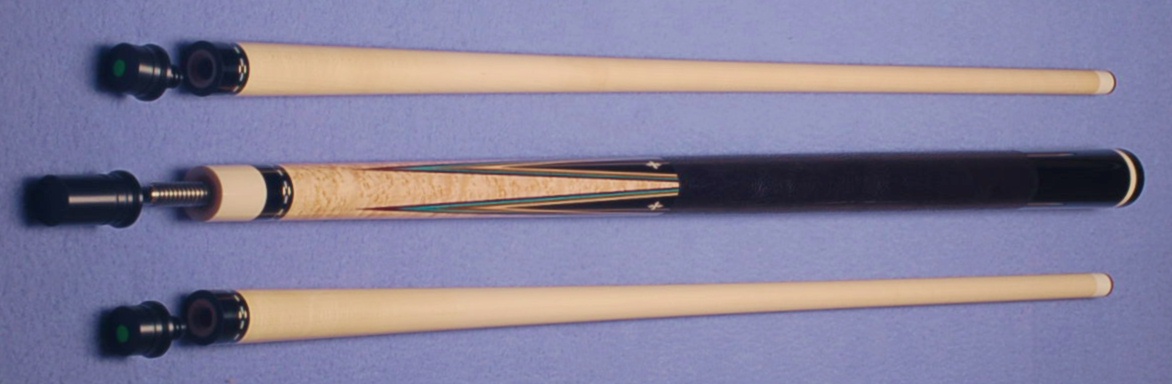

All components are made in house except for the tips. His favorite woods to use are snakewood, ebony, cocobolo, purple heart and birdseye maple.

ARIEL CARMELI CUE VS QUEUE FULL

Although he’s used the full splice technique in the past, currently he’s choosing to finish the ones already in production and then continue with short splice only. While he typically creates six custom cue designs per year for dealers, they are highly customizable by changing up the wood and other components of the cue as well as adding more detail. Once materials are located, then after the wood stops moving and is cored, Ariel says production takes about one year from start to finish. He states that being on the West coast often creates a challenge as well because as product becomes available, the East coast typically has first access due to being three hours ahead. He couldn’t get phenolic for seven months and the company in Canada where he gets his shaft wood, was shut down for five months. He enlightens us that production has been slowed lately due to Covid as many materials have been difficult to come by. He says it’s difficult to get enough quality materials to match product designs to fill orders. Ariel states the hardest part about being a cue maker is first “finding customers getting someone to try your product without dismissing you.” Now after being a long-established cue maker, the most challenging part is producing what everyone wants. Although he describes his shop looking as though a “nuclear bomb went off” he manages to produce some incredible playing cues out of the chaos. For the past 20 years, he has worked out of his 700 sq ft shop near his house in Eastvale, California. Ariel decided to keep it and in 1992 established Carmeli Custom Cues.Īriel has been a full-time cue maker since 1994. Inspired by this, his friend Del Ramos surprised Ariel with a logo he’d created for the new cue maker. Ariel was a quick learner, and it wasn’t long before he began receiving his own orders to fill from people wanting a cue from him. He asked Tad to give Ariel some pointers and for the next year Tad would come in for an hour every other weekend and give Ariel lessons on building cues. Fortunately, the venue’s owner, Rick Landsburg also happened to be a sales representative for Hall of Fame cue maker, Tad Kohara (TAD Cues). Ariel laughs about his “extensive” lesson on the lathe from the venue’s manager, Robert Wong: He received all of about seven minutes of instructions and then spent the next two days getting comfortable using the lathe.

He had never used a lathe before but was confident that if he could see the different parts of a cue, then he could effectively put one together. While he had a strong background in making and repairing furniture, it wasn’t long until he was asked to use his skills for cue repair. In the shop they also had furniture repair, which is where Ariel started. In 1991, Ariel began working at a billiard supply company called Best Billiards in Santa Ana, California. He also retained employment as a plumber, but it was when the next recession hit that he was forced to pursue another career path. Prior to becoming a cue maker, Ariel developed his wood-working skills while building furniture under his brother’s high-end sign shop called “Carmeli Design Group”. The best part about being a cue maker? The ability to “be a stay-at-home dad.” Ariel Carmeli of Carmeli Custom Cues appreciates the finer things in life and is this month’s feature of “Meet the Cue Maker.”Īriel Carmeli, 52, resides in Eastvale, California with his wife Debra and their family.

0 kommentar(er)

0 kommentar(er)